The quality of the components, the high technology used in the production of the mechanical parts, in the finishes and in the surface treatments, the constant and checked quality system UNI EN ISO 9001 which covers the company’s entire production, allow Grues Treuil to offer a product in line with the latest international standard.

Our product range comprises individual need of crane production and service companies and offers:

- Durability combined with excellent price/performance ratio.

- spare parts policy bringing cost-effective aftersales service

- Attractive delivery terms even for non-standard products

- Robust, safe and reliable components

- We do adapt our standard products for certain markets and regions

- Full range of products for any crane manufacturer

- wide range of technical characteristics of the products thanks to our knowledge of the market

- Longer life of the products

Grues Treuil mainly offer:

- Electric Chain Hoists

- Electric Wire Rope Hoists

- Cranes & Components

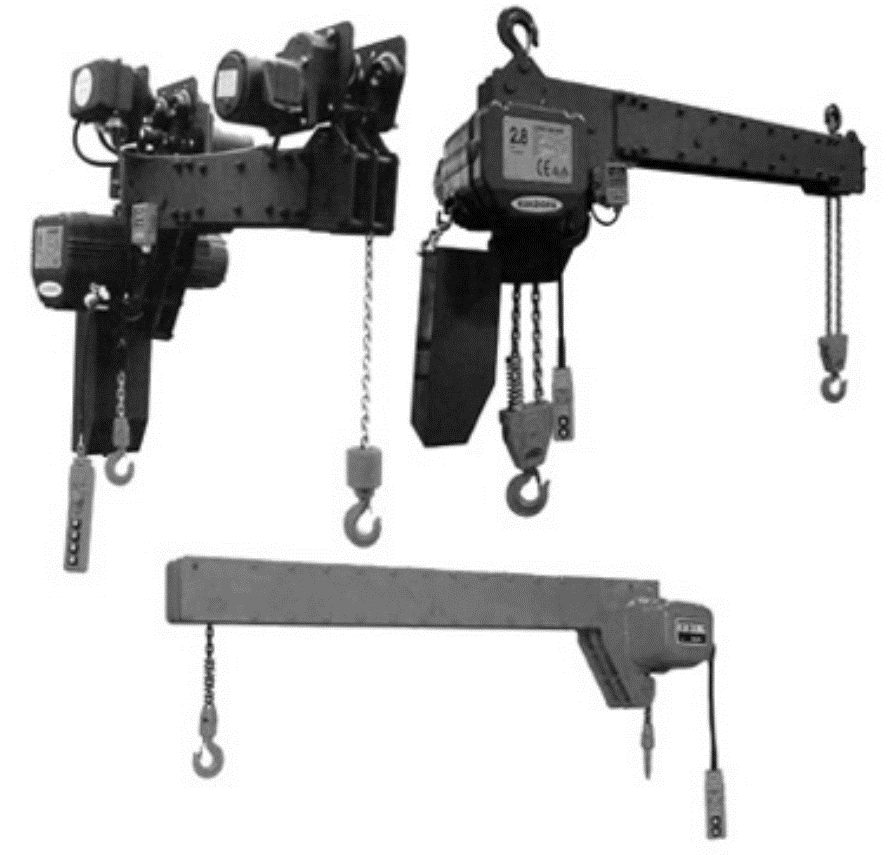

Electric Chain Hoists GTC Series

Chain hoist line can be distinguished by its compact design, its superior quality and high standard of safety. Every hoist is confirmed by the CE marks it is load tested before being delivered to the customers.

The high-strength alloy on the components and parts is going through multiple special technology for heating processing, so that it is high-strength and good abrasion performance; the up and bottom hooks of our hoists are made of high-strength alloy.

Electric Chain Hoist – Suspended Type

- Allows the reaching of the installation point with the hook and the related chain, without having to lift the entire weight of the hoist.

- It is particularly suited to the entertainment industry and when frequent installation and dismantling at greater heights are requested.

- Capacities from 125 up to 5000 kgs.

- FEM (ISO) : 2M (M5)

- Lifting speed : mt/min. 4 or 8

- Chain box in cloth

- Other characteristics as per GTC in fixed execution

Electric Chain Hoist with Hand-push trolley

- Horizontal movement by push/pulling the load

- Recommended for light duty and short load travel only

- The push trolley is adjustable for variable flange widths, fitted with steel machined wheels, permanently self-lubricated bearings, fitted with anti tilt derailment bars and equiped with shock absorbing buffers.

- Capacities from 125 up to 5000 kgs.

- FEM (ISO) : 2M(M5)

- Working at one or two lifting speeds

- Other characteristics as per DMK in fixed execution

Electric Chain Hoist with Electric trolley

- CT Movement operated by the push button from pendant attached to the hoist

- Recommended whenever the manual push is not feasible ; i.e.for heavy duty use.

- The electric trolley is adjustable for variable flange widths accordance with Beam or Girder on which its going to be fitted.

- The trolley can be supplied on demand only

- Electric limit switches to limit the CT movement of the electric trolley on the beam

- Capacities from 125 up to 5000 kgs.

- FEM (ISO) : 2M (M5)

- Other characteristics as per DMK in fixed execution

Electric Chain Hoist with Electric trolley – Low headroom execution

- The best solution to get the maximum hook-run; fitted on a frame with a return system for the chain, the frame is mounted on 2 trolleys.

- Available in electric or hand-push execution

- Capacities from 125 up to 5000 kgs.

- FEM (ISO) : 2M(M5)

- Lifting and travelling at 1 or 2 speed

- Other characteristics as per DMK in fixed execution

Electric Chain Twin Hook Hoist – 500 Kg – 10 Ton

- This type special Chain Hoist comes with Classification : FEM (1BM) / ISO (M3).

- These Hoists are Stable and balanced designed. These Comes with Motor & Brakes with ‘F’ Class.

- Preferably used When large , long load transports demands stable and safely simultaneous lifting.

- Ambient Temperature : -20℃ ~ +40℃

Electric Wire Rope Hoists

Electric Wire Rope Hoist Normal headroom or articulated monorail trolley – MX Series

- Hoist with the suspended type mechanism worldwide followed by many Crane suppliers.

- Hoist capacity is from 1.000kg to 20.000 Kg,

- The hoist is suspended and assembled to the trolley that runs on the lower flange of the beam

- The trolley is also available as articulated version to run on curves

- Application in single girder cranes where below-the-hook space is not important factor.

- Normal headroom design enables the hoist to operate directly under and parallel with the crane or runway beam.

- The trolley is composed of an idler wheel assembly and a drive wheel assembly, both have two wheels made of machined pressed steel with spherical bearings.

Electric Wire Rope Hoist Low headroom type – MX Series

- Hoist with the low headroom now mostly demanded features as per our order data.

- Maximum capacity is up to 20.000 Kg,

- The hoist is set-down on the trolley that runs on the lower flange of the beam.

- Supporting bars with circular cross sections which support the hoist in a set-down position.

- Most common solution for single girder crane with demand for optimized below-the-hook building working space. Compact design for maximum space utilization.

- The trolley is composed of an idler wheel assembly and a drive wheel assembly, both have two wheels made of machined pressed steel with spherical bearings.

- The wheels of the drive wheel assembly are opposing and have a crown gear wheel and are connected by a transmission bar.

- The steel supporting plates are adjustable along the bar and have anti derailment device.

Electric Wire Rope Hoists New GT Series with Single & Double Girder type

- Allows the reaching of the maximum hook approach and low headroom application.

- Capacities from 2000kg up to 15000 kgs.

- FEM (ISO) : 2M (M5)

- Falls 2/1 to 4/1 depending on application

- Trolley Speed : mt/min 5 to 20

- Lifting speed : mt/min. 1 to 4

- Other characteristics as per MX in fixed execution

Electric Wire Rope Hoist in configuration with double girder trolley DMX series

- Maximum capacity 20.000 Kg for hoists 2 or 4 rope falls with double girder trolley span 1000 mm or 1200 mm

- Maximum capacity 60.000 Kg for hoists with double girder trolley span 1400 mm or 2240 mm or 2800 mm

- Electric double girder trolleys travel on top of rails fitted on the crane beams, this allows the maximum hook path.

- One or two hoists on one trolley.

- Parallel or perpendicular alignment to the main girder related the building design and application.

- Option for tandem work of two hoists or two trolleys. Suitable for transportation of long materials.

- The wheels, pressed from carbon steel, rotate on permanently lubricated bearings.

- The trolley has an ant derailment device.

- The trolley motor is conical self-braking type, progressive start up and can be supplied :

- 1 travel speed of 8 m/min or 10 m/min or16 m/min or 20 m/min

- 2 travel speed of 16/4 m/min or 20/5 m/min

Standard Crane Kits

Our crane kits save your time for design and crane assembly.

Many standard components could be combined to wide variety of configurations to meet variety of specific customer requirements. We could support your fabrication drawing for main girder under request with focus not only to the safety, but also on cost-effectiveness.

All components offered with attention to detail – including electrical plug and socket connections, towing arms, buffers and marking and brand stickers.

Electrical components are coming from reputable international suppliers.

Standard components included in our crane kit:

- Monorail or double rail hoist unit

- End carriages (end-trucks) with connection plates and bolts

- Travel drives – motor-reducers

- Crane electrical control panel

- Push button control pendant

- Festoon system and cable set